Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Warehouse # 7, 4th Street, Umm Ramool, Dubai, 30183, Dubai

🚀 Elevate Your Drying Game!

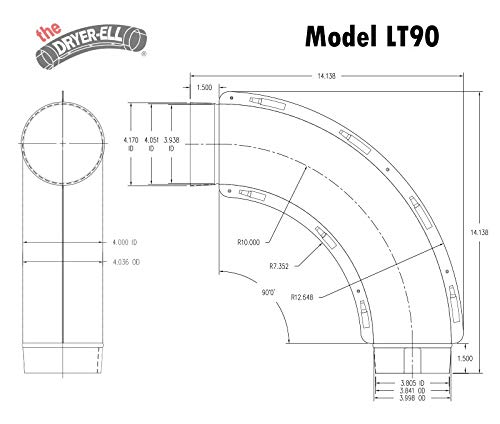

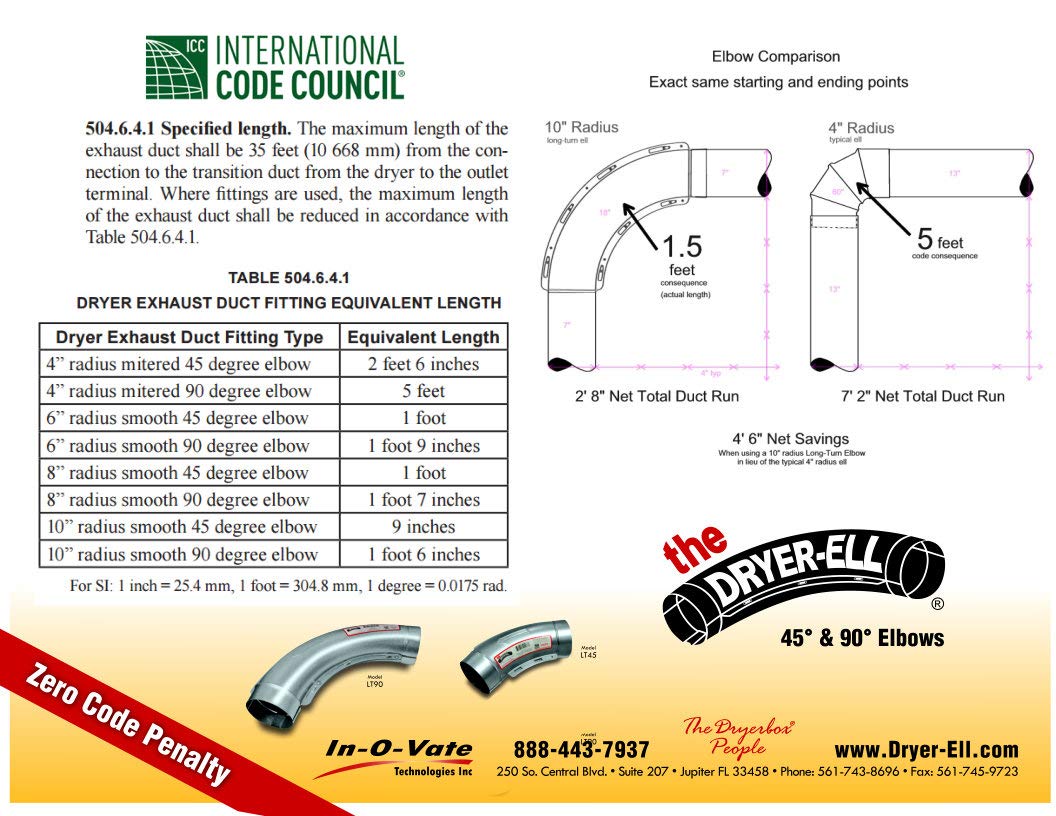

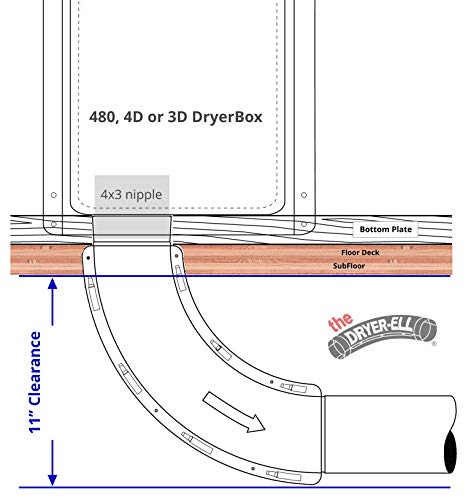

The Long Turn 90 Degree Dryer Elbow by The Dryer-Ell is a high-efficiency duct accessory designed to enhance airflow and reduce drying times. With a 10-inch radius and durable metal construction, it minimizes lint buildup and maximizes dryer performance, making it an essential upgrade for any modern laundry setup.

| Brand Name | The Dryer-Ell |

| Model Info | LT90 |

| Item Weight | 1.8 pounds |

| Package Dimensions | 19 x 7.8 x 2.4 inches |

| Item model number | LT90 |

| Is Discontinued By Manufacturer | No |

| Part Number | LT90 |

| Color | Silver |

| Material Type | Metal |

A**L

looks good after it is put together

Some people are complaining about that they do not supply screws, if you do not have the sheet metal screws typically used for metal ducts then you probably should pay someone to do the work. After putting it together it is going to work great. A little expensive but if you want maximum performance there is no other choice. I drilled new holes to put it together, their holes did not line up well. Also the exit end fits into the next pipe (no crimping required) and the entrance end fits over the incoming pipe as it should.

G**G

It might save you trouble or vexation to read this and examine the photo.

This is a review of Long Turn 90 Degree Dryer Elbow 4 Inch 10in Radius by The Dryer-Ell, in case Amazon or hackers blend my review with ones for starfruit marmalade. Before you can install this you must assemble it. Perhaps you will be lucky and get ones that are not very slightly curved where they ought not to be, and that go together quickly. If you are not lucky, read on, and look at my photo. Supplies needed: high temperature silicone sealant (I bought Rutland Sealant Silicone BLK 2.7OZ, pictured), spring loaded (or other style) shop clamps, or, in a pinch, 2 inch binder clips, plenty of paper or cloth shop towels, and a calm spirit. I used Workpro 8-Piece Metal Spring Clamps, pictured, because I owned them, but any appropriately sized shop clamps will do. Assemble and clamp 24 hours before installation (so the sealant can cure and not get smeared everywhere, and so the the clamps will no longer be needed). Lay the two halves out and examine them carefully. I had to bend some of the tabs a bit so they would permit assembly. The point is to look and analyze before applying sealant or force. Apply the sealant to one of the two surfaces that will be apposed. Assemble with care. I had to use some force. Clamp with care, making sure all tabs are where they should be before clamping. Examine the inside, looking for light entry along the seams, and apply more sealant to the outside at places where light enters. Let dry at least 12 hours before unclamping, and at least 24 hours before using. If you assemble more than one of these, you will learn from experience and be less vexed with successive acts of assembly. Also, you might need very many clamps indeed. I gave this a four star review because it is a useful and well thought out product and I expect it to resolve difficulties with my dryer's venting system. The project is complete: it performed as expected. I expected it to be easier to assemble.

T**R

Adds no extra feet of duct length compared with regular 90

I like to find solutions that my contractors haven't seen before and this is one of them. Needed a 90 degree bend but did not want the extra 5 feet or so resistance a regular 90 adds to the vent length and found this option which has zero extra impact on vent length other than the length of the piece itself which is around 18 inches from memory. Fantastic. So two of these is 3 feet of length not 10. Important when following code. The vent this is used with has a dryer booster as the run to the outside is very long so every foot saved is a big help.I know many reviewed this but not many seem to point out this benefit. A further plus point is that it should make cleaning duct much easier than a regular 90.Lastly, I couldn't resist assembling it before I gave it to my contractor and it was not too hard. Once joined you can see light between the sides when you look at it from the inside so obviously it needs tape and/or mastic and screws

T**E

Fast and easy

Quality, easy to use and install

P**K

Works well

Great for a dryer vent. Remember to tape the edges and cover with mastic.

M**L

Review

Great idea ,but didn’t work for my application .

A**R

worthwhile purchase

It does what it is intended to do. It took some persuasion to get the two different sides matched up and married together, but once I got that done it was fine.

J**Y

Nice idea, but cheaply implemented

This unit comes as 2 clamshell-halves of zinc-plated steel which need to then be assembled by the customer after delivery. The last thing most people want to have to do is complete the assembly of sharp sheet-metals parts without slicing their fingers up in the process. The half-pieces are slid together using the stamped-out tabs and slots. There are then 5 small holes which are apparently for the insertion of very small (#4) sheet metal screws to keep the assembled halves from sliding apart after assembly. BTW, no screws or instructions are included so you are on your own...This was done to increase the profit margin on the product, as stamped steel halves are much cheaper to produce than a continuous sweep like an EMT conduit elbow (long radius). A full sweep 4" galvanized EMT fitting is about the same price (except for the shipping of course).Additionally, after the halves are assembled, the dryer 90 degree sweep then needs to be "taped" together with adhesive-backed aluminum foil tape because there is a significant "gap" from the inside-to-outside of this elbow which would allow for leaks (until your dryer lint maybe eventually plugs them up.Again, at this price point, I would expect a completely assembled unit ready for use.But not to be an "all-negative Nellie", the concept is an excellent approach to relieving any excessive back-pressure from the exhaust piping which can dramatically increase the time required to dry a load of clothes. I am only criticizing the end-implementation from the consumer's perspective. A completely continuous, and seamless, 4" "sweep" would be much easier for an end-user to install.

Trustpilot

2 months ago

3 weeks ago

3 weeks ago

1 month ago